Introduction to Black Powder Cartridge Rifle

Loading

By

Chuck Raithel

11 JUL 01

1. Introduction

2. Special Equipment

a. Drop Tube

b. Bullet Molds & Nose Punch for Lubesizer

c. Lead Melting Pot

d. Lubesizer

e. Compression Plug

f. Scale(s)

g. Blow Tube

3. Components

a. Brass Wads

b. Primers

c. Powder

d. Bullets

e. Indexing

f. Lube

4. Loading Techniques

a. Powder & Compression

b. Bullets

5. Shooting

a. Working Up a Load

b. Use of a blow tube

6. Load and shooting records

7. Favorite Loads

8. Loading for the 45-70 “Trapdoor” by “Minnesota Al”

Section 1

Introduction

Welcome to the interesting and sometimes frustrating world of Black Powder Cartridge Rifles (BPCRs). I’ve written this short piece on the basics as an attempt to assist new shooters interested in this sport. It is not intended for someone that isn’t familiar with basic reloading concepts. This is in no way an inclusive work; my methods are not the only way to make your rifle shoot well! Many of these ideas/techniques I’ve either learned the hard way, or gotten from other shooters. One of the first steps that you, the new shooter, must undertake is establishing your own personal goal. What level of accuracy are you looking for? I’ve gotten my rifles to the point of delivering 1-1.5 MOA for ten shot groups. It has taken time and a lot of experimentation. If you’re a casual shooter, only intent only on plinking, then some of the following steps may be omitted. There are some excellent references available. The SPG book, “ “SPG Lubricants BP Cartridge Reloading Primer” written by Steve Garbe and Mike Venturino is a good start. It has step by step simple instructions that are easy to follow. The series of books written by Paul Matthews are also excellent. Another excellent source of information is Brent Danielson’s Website: Making, Loading, and Shooting Paper Patched Bullets http://www.iastate.edu/~codi/PPB/PPB.html#Loading_techniques

One word of caution is required here. Read everything you can get your hands on, listen to experienced shooters, but believe nothing until you’ve proved it in YOUR rifle. These rifles are capable of some remarkable accuracy if the shooter/reloader pays attention to detail. Remember; “Consistency breeds Consistency”.

Section 2

Special Equipment

For the sake of brevity, we’re going to assume that you’ve got all the basic equipment required for reloading and you’re familiar with reloading procedures. If you’re not, it’s time to learn some basics before attempting this! In this first section, I’ll cover some of the peculiar equipment/tools required to load and shoot a BPCR.

a. Drop Tube: This is a rather simple but necessary piece of equipment required to assemble good BPCR loads. Powder is slowly poured through the drop tube to settle it in your case. It’s been found that powder that’s been poured through a drop tube burns more consistently and cleaner. Also, it’s impossible to fit some loads in the case without using a drop tube! I’ve talked to shooters that have experimented with vibration to settle their powder, but none received more consistent results than with using a drop tube.

A drop tube can be made as simple or elaborate as you’d like or they can also be purchased complete. It’s nothing more than a piece of brass tubing or an aluminum arrow shaft about 3/8ths diameter, 24-30” long, that is used to settle your powder in the case prior to compressing it or seating your bullet. You can make a wooden stand and use two brass eye screws to hold your tube. I use rubber “O” rings on the tube to hold the tube in place and adjust the height, I add another one at the bottom that fits over the case mouth. Add a funnel on top and you now have a drop tube!

b. Bullet Molds: You’ll need to purchase a suitable mold for your caliber and rifle. Usually heavier is better in BPCR. Do not try to save money here. IMHO molds made by Lyman, SAECO, and RCBS are good starting points for an “off the shelf” mold. You can buy commercially cast bullets, but to get the consistency required you’ll have to cast your own. Books have been written on this subject alone so I’ll defer to the “experts”. I will say that I do not know anyone that is having any success with Lee molds.

c. Lead melting Pot: This piece of equipment really depends on how you intend to cast your bullets. If you intend on using the ladle method you can even get away with using a Coleman Camp Stove and an old cast iron pot. Some casters even use a propane fish cooker. If you’re going to bottom pour as I do you’ll need an electric furnace such as the RCBS Pro-Melt. Regardless of method selected your heat source must maintain your alloy at a constant temp. Use a thermometer! Temperature variations will result in variations in bullet diameter and weight.

d. Lube Sizer: Once you get into casting, you’ll probably need a sizer. I say probably, because some shooters “pan lube” and don’t use a sizer at all. I do, it makes lubricating your bullets a breeze and when sizing .001 or less it doesn’t distort your bullet. I.E. using a .460” sizer on a .459” bullet doesn’t distort or size the bullet, but does apply the lube quickly. (see notes on Indexing) You’ll also need a top punch for your lubesizer that fits your bullet, these should be available from your mold manufacturer.

e. Compression Plug: this is a nifty little tool that allows you to compress your powder prior to seating your bullet. Many shooters like to compress their powder to different degrees. For some powders, compression allows for increased velocity and a cleaner burn. Since fouling is one of the principle concerns of the BPCR shooter the right amount of compression, is extremely important. I’ve found that newer lots of GOEX Cartridge grade powder seem to like around .300” compression to burn cleanly, while Swiss powder seems to like considerably less compression.

A compression plug is a threaded plug that is slightly undersized for the inside your case. It screws into your expander die or you can buy a separate die body for it. It’s available from Buffalo Arms at (208) 263-6953, or http://buffaloarms.com/ and costs about $16.00 as of this writing. Another method is to make a compression bullet made of a harder alloy or turned out of brass or steel. This takes the ability to use a lathe and access to one. The “bullet” will have to be of smaller diameter, exact length, and close to exact shape as the bullet you’re shooting. Whatever method you prefer, be wary of compressing powder with your bullet. Due to the relatively soft bullets used in BPCRs, compressing with your bullet can deform it and lead to accuracy problems.

f. Scale(s): Many other shooters, myself included make use of an electronic scale for weighing bullets. Bullets are weighed as an indicator of consistency. When dealing with a batch of 100-200 bullets it’s nearly impossible to weigh them using an older balance beam scale and retain your sanity and have time left for anything else. The electronic scale makes weighing bullets fast and painless. You won’t need one right away, but I guarantee you, you’ll get one sooner or later. For weighing powder I prefer the old balance beam style. I weigh my charges, and a balance beam scale shows gradual increases in weight better.

g. Blow Tube: This is probably your simplest piece of equipment and your most important! I’m willing to bet that improper use or lack of Blow Tube use has caused more problems to new BPCR shooters than anything else has. Black Powder fouling needs moisture to stay soft. Without moisture and a good BP lube you will get hard fouling. This will ruin accuracy very, very, quickly and can result in a leaded barrel.

A blow Tube is a tool to get moist air from your lungs into your barrel. Notice, I said barrel not chamber! It can be made of plastic tubing that fits into the chamber, but stops at your rifling. It can also be made from a modified case with tubing attached. I like a short tube to keep condensation in my barrel. However, make sure that the tube is long enough for you to use while adjusting your sights. This will save you time on the firing line and keep you from having to adjust your position and roll out from under your gun. Use clear plastic, and if you see condensation building up, shorten the tube. You want that moisture in your barrel, not your blow tube! You can buy one or you can make it yourself.

Section 3

Components

a. Brass: Brass preparation is often overlooked, but can be a substantial contributor to good or poor accuracy. First off, buy as much of one lot or batch as you can of your brass. It is not uncommon to need up to 300 rounds for some of the larger matches. Do the math, with some of the larger caliber’s this can get expensive! Once I get my brass I:

(1) Full length size it for the 1st firing, subsequent firings I only neck size about .5”. Some shooters do not size at all. You’ll have to figure out what degree of neck tension your rifle likes.

(2) Trim it to a couple .001” under size and smooth case mouths

(3) Clean-up and re-cut primer pockets

(4) De-burr the flash holes. (I do not enlarge them)

(5) I then weigh brass and segregate it into 50 rd lots by weight. Reasoning: If brass has different weights and the outside diameter is the same, than the internal diameter must be different. This leads to varying internal volume and subsequent pressure variations. Won’t matter at the closer ranges, but when shooting at distance….. It’s then indexed, by filing a small notch into the case rim. A Dremel tool with a cutting wheel attached works great! This helps in orientating your brass when loading/firing and when indexed in different places on the rim, helps in keeping brass lots separate. (I’ll cover indexing later).

(6) Your brass then needs to run through your expander die. This expands the case back up to a few thousandths under your bullet diameter and bells the case to allow you to seat your bullet. I like to limit my belling to the minimum that will allow the bullet to enter the case cleanly. This limits my chances of overworking my brass. It is commonly held belief that a slight bell left in your case helps center your bullet in the barrel. I have one rifle that prefers a bell left in the case, my other rifle prefers it removed during bullet seating. Buffalo Arms offers custom diameter expanders that can fit your needs.

(7) After firing be sure and clean your brass promptly. This is probably the worst cleaning chore involved with BPCR shooting, and this isn’t really that bad! At the range I use a DAT De-capping Tool sold by Buffalo Arms to de-cap my brass after firing. Other shooters I know use a Lee hand press and a universal de-capping die, whatever works for you. I then soak my brass in a mixture of Mr. Clean and water. If you do this as soon after coming off the line as possible, cleaning is no big deal. Once I’m home I again wash my brass in a mixture of hot soapy water, rinse and dry them. Be sue to clean the insides too, BP residue can and will build up causing case capacity and neck tension problems. If you’re using LDPE wads pay special attention to the inside of your case necks, keep them clean! A .50 bore brush in a variable speed drill or screwdriver works well for this. After my brass is dry, a couple hours in a vibratory cleaner is all it takes.

After completing the above steps I now have brass that’s fire formed for my chamber. Most of the serious shooters won’t start working up a load until they have a quantity of formed brass. Once you have a good quantity of formed brass your load development can begin in earnest.

b. Wads: the function of the wad is to protect the bullets base, assist in sealing the bore, and also prevent lube from migrating into your powder. BPCR wads can be simple or pretty complex it’s up to you. On the simple side you can use punched out milk carton or tablet backing. When using milk carton wads be sure to place a newspaper wad between the milk carton and the bullet. The wax in the carton may cause the wad to stick to your bullet resulting in a possible flyer. I prefer veggie wads, these are made out of a gasket type material that Buffalo Arms sells. Some shooters use a low density plastic called LDPE, which is similar to the material used in coffee can lids, again this is available through Buffalo Arms. Wads also come in different thickness, two of the most common are; .030’, and .060”. Only testing in your rifle will tell which is best. You can buy precut wads or wad material and punch them yourself. A change in wad thickness or materials can have a dramatic effect on accuracy. There are a couple of different punches you can buy.

The first and most primitive is the kind you hit with a hammer. It may well be the way the old buff hunters and Creedmore shooters did it, but if you cherish your hearing and spousal bliss, you’ll buy the second kind. This is the press-mounted punch as made by Fred Cornell. It is a 1st class, piece of machinery, and is a joy to use. You can literally punch out hundreds of wads in minutes, and it’s actually enjoyable! The Cornell punch is also sold by Buffalo Arms. By now you should be catching on that these guys are a major source for BPCR equipment and materials. Buy one, and you can then wander around your house looking for materials to create wads out of.

c. Primers: When I first started BPCR shooting the Federal 215 magnum primer was believed to be the “Standard” in BP primers. The SPG book recommended a hot primer and also went on to recommend the FED 215. These days shooters are experimenting with different primers to include Large Pistol primers with varying success. In my 45 2.1” the FED 215 works extremely well. I get a good SD (Standard deviation) and ES (Extreme Spread) with them. My fouling is also light, which tells me that in this cartridge, with this lot of GOEX, with this amount of compression, Federal 215’s are working. This last sentence will give you a small idea of the variables involved.

I believe that a couple variables come to play in primer selection. First off, I’ve made the observation that a lot of the shooters advocating pistol or softer primers seem to be shooting light bullets, in smaller cases, with light neck tension. I firmly believe that when a primer ignites it can and sometimes does cause a bullet to “jump” prior to initiating a burn and building pressure. With light bullets and limited neck tension this “jump” is aggravated and can cause accuracy problems. I also believe that the larger calibers using more powder, need a hotter primer to get a clean, efficient burn.

Generally, primers won’t make or break your accuracy. What I mean to say is, a change in type or manufacturer won’t cause 6” groups at 100 yards go to 2” groups. They may very well cause 4” groups at 200 yards shrink to 2 or 2.5” groups. They may also cause your SD to drop from 8 Fps to 5 Fps in a ten shot string. At 100-300 yards no big deal, at 1000 could be 10 inches! The right primer might also be responsible for a much cleaner burn and decrease your fouling significantly. This becomes very important when you’re shooting a match in which sighters between targets aren’t allowed. Shooting dirty and accurately becomes essential. The right primer for your load just might enable you to do this. For starters I still go with a FED215, it is a very good primer and on average produces good results in the larger cases. Once I’ve gotten my basic load worked out, then I mess with primer experimentation. As with all load development, only change one component or variable at a time.

d. Powder: There are now four major makes of Black Powder available on the American Market: Goex, Elephant, KIK, and Swiss. I haven’t experimented with any of the BP substitutes, and I probably never will. In my mind they offer no ballistic advantage, cost more, and may even be inferior to straight BP as a propellant.

Some shooters are reporting excellent results with both elephant and Swiss. The newer Swiss powder is reported to be comparable to the fine old sporting grade powders of the last century. I’ve found it to give higher velocities, be more consistent lot to lot, and leave a softer fouling. It is however, much more expensive than either Elephant or Goex. In the larger cases this can be a valid concern. I’ve recently worked up a load for my 45-2.6” SS using Swiss 1.5F. My new load shows accuracy on par with my best Goex Cartridge loads, velocity increased 30 Fps with 5 grains less powder, and fouling is reduced. Whether the benefits are worth the additional price remains to be seen. In my testing, Swiss did not like a lot of compression. As a matter of fact it pretty much hated it. As compression levels increased, accuracy and chronograph data suffered. I finally settled on .140 compression.

Elephant powder has also been given high marks lately. At first it was reported that it lacked the velocity of GOEX and also the consistency. Lately many shooters have been reporting that it’s much improved in the velocity department. In addition they also say that it leaves a softer fouling than GOEX. In the big caliber’s this becomes important when shooting long strings “Dirty”. I’m most familiar with Goex Back Powder so I‘ll limit my writing to this brand.

BP is broken down in grain size; FG, FFG, FFFG and Goex Cartridge Grade, each with a different burning rate. With Goex sizing the more Fs the smaller the grains and the faster burning the powder is. Goex Cartridge (my favorite) seems to be a mix of FFG and FFFG with graphite coating. Your burn rate is important as a means of controlling your muzzle velocity and therefore recoil. In the larger cases you can go with a larger grain size and slow things down a bit and get some relief for your shoulder at the same time. Also in the larger cases, too small a grain size can lead to excessive hard fouling. Some shooters are using a mixed blend, that is they use a fine powder priming charge with a coarse powder main charge. This method works for them and enables a cleaner burn, and higher velocity without the concerns of hard fouling often associated with shooting too fine a grade powder for caliber.

Regardless of the powder used I like to sift it prior to loading. The purpose is to remove BP fines and dust from your powder. They both are usually found in the bottom of your powder container and can lead to an inconsistent burning rate. Cal Graf Design at http://www.mcn.net/~calgraf/ offers a neat tool to do this. Basically it’s a wooden box containing screened drums of different mesh size. You simply pour powder into the appropriate drum, rotate it in the box and you’ve removed the fines and dust or separated sizes. As with all Cal Graph products, it’s well made and will last a couple of lifetimes.

Weighing Bullets to .10 Grain tolerance

e. Bullets: First off let me say that for good BPCR bullets you’ll have to start casting your own. Most commercial casters are not set up to make bullets for the BPCR shooter. Their alloys are usually too hard and their lubricant is made for smokeless powder and is incompatible with BP. There are a few companies that do cast BPCR bullets, however usually their consistency isn’t up to par. With commercially cast bullets you’ll find your bullet weights varying, imperfect bullets and bullets with deformed/damaged bases. All of which can and usually are detrimental to good accuracy. You can also buy match quality bullets, but be prepared to pay dearly for them.

There are several companies now offering molds with good BPCR bullet designs. For entry level .45 caliber there’s the Lyman 457125 and 457132, RCBS BPRC, and SAECO 745. These mold usually cost around $40 and are also found in stock at most reloading mail order companies. If you want to get into the custom realm, NEI, Brooks, and Paul Jones also offer excellent molds. For the custom mold, be prepared to pay $100 or more and the wait could last up to six months for some. Just remember you are looking for a BPCR bullet mold, heavy for caliber with big wide grease grooves.

Once you’ve settled on a mold design, it’s time to choose your alloy. This is extremely important and can only be decided by testing. Most shooters are using an alloy of either 20-1 or 30-1, this should tell you something. By choosing a harder or softer alloy you can control your bullets diameter and weight to some degree. Harder alloys shrink less and yield a larger bullet. The opposite is true for softer alloys. In some rifles a softer alloy is needed do to compensate for an oversized bore. The softer bullet can “Bump Up” upon firing, sealing the bore and delivering good accuracy. With this same rifle a harder alloy might give dismal accuracy and result in leading. With some bullet designs a softer alloy can cause problems. On bullets with long bore riding noses, the nose can slump to one side upon firing. This can also lead to flyers and erratic accuracy. Most BPCR shooters prefer softer alloys of 20-1 or 30-1. These ratios are a pretty good starting point. How your bullet/alloy combination shoots in your rifle will be the deciding factor.

You will have to either buy your alloy premixed or you can scrounge and make your own. Both methods have their pros and cons. Buying premixed alloy can get expensive; some go for as high as $1.00 per pound. At 1¼ oz per bullet this adds up very quickly. However to some it’s well worth the cost. With a known alloy from a reputable dealer, you know exactly what you’re getting. Unknown metals in your alloy can lead to casting problems. Also your alloy is repeatable, last month’s bullets are the same as this month’s bullets. When shooting large matches where you might be using bullets from several casting sessions, this becomes important. Being cheap, I prefer to blend my own. Scrap lead can be bought for as little as 30-40 cents a pound, pure tin can be found for about $8.00 a pound. I use a propane fish cooker and a cast iron pot that holds 50 pounds of alloy. I mix up my alloy, clean it, and use an old muffin tin to make ingots. I separate the ingots in fifty-pound lots as they come from the pot and mark them with a magic marker. When casting, I use ingots from the same alloy lot to cast a batch of bullets. It takes more effort than buying premixed alloy, but the savings can be substantial.

f. Indexing: Now’s as good time as any to discuss “indexing”. I like to index my cartridges from loading through shooting. Indexing insures that any imperfections in your cartridge are introduced into your rifle’s chamber the same way each time. It’s nothing more than orienting your case in your case sizing die, bullet in your bullet sizing die, sized bullet in your case, and your loaded cartridge in your chamber the same way each time. When casting bullets I scribe a small line on the base of my bullet one side of the bullet seam as I cut the sprue. I index my bullets using the bullets “seam”, while keeping my scribe line always on the left side. When sizing my bullets I insure that this line is always on the same side of the sizing die and that my seam lines, line up. When seating the bullet in the case I make sure that the seam line, matches up with a notch I filed in my case rim, scribe line on the left. And lastly, when I shoot, I insure that my case notch is in the 12 “O” clock position in my chamber.

g. Bullet Lube; First off let me say that BP bullet lube is significantly different than the smokeless bullet lubes that you’re probably used to. Besides the normal function of helping to prevent leading, a good BP lube helps keep your powder fouling soft. Without accomplishing this, accuracy is impossible without cleaning between shots. This is another reason to insure that you pick a bullet design with large enough grease grooves to carry lube the length of your barrel.

Luckily there are some good lubes on the market and also a few homemade lubes that work very well. For commercial lubes, try SPG mad by Steve Garbe, or Lee Shavers Moly Lube. I’ve tried both and can recommend them highly. SPG is a little on the expensive side, but it is a solid performer, Steve Garbe has won several championships using it. Lee Shaver’s Moly Lube is newer, but it’s what I rely on now. It works extremely well and allows long shot strings in my 2.6”, even in hot dry weather.

A good homemade lube is Paul Mathew’s as described in his book. It’s simple to make, inexpensive and works quite well. For my first two years of shooting I used this lube exclusively with excellent results, won some matches and shot some very good groups. To make Mathew’s lube:

(1) Melt 4oz by weight bees wax in a Pyrex dish in your microwave on high 12 minutes or until melted.

(2) Add 2oz of pure Neatsfoot oil by volume (use one of those little plastic measuring cups). Pure Neatsfoot oil can be found in most well-stocked Tac shops.

(2) Add in 2oz of Murphy’s oil Soap, pour slowly, and be careful! When you’re adding the soap it has a tendency to boil over. The soap causes spontification, which raises the melting temperature of the lube. Stir the mix until all the lumps are gone. Then either pour it into a suitable container or directly into your lubesizer.

Another good home made lube recipe offered by Jeff Sluder: “It goes by a bunch of names (dale53 aka Dale McGee, has some rather colorful names for these home brew things like Friendship Speed Juice for cleaning stuff, Ed's Red for a home brew solvent, etc.)”

5 parts bees wax

4 parts canola or olive oil (I use olive oil)

1 part Crisco brand shortening (tried other cheap stuff but Crisco works best - the fact that I work for the company that makes it has nothing to do with my preference either...).

(1) Melt the bees wax in a double boiler or on a burner set REAL LOW if you can watch it melt.

(2) Add the canola oil and stir until mixed. Add the Crisco and stir until well mixed.

(3) lube the bullets.

It works in both hot and cold weather. Add more oil to thin it up some and it makes a great patch lube for round-ball muzzleloaders.

It’s important to remember that fouling is controlled by a combination of; your lube, powder compression, and blow-tube use. Some “old hands” recommend changing your lube recipe based on expected temperature. This idea has a lot of merit with the homemade lubes. The consistency can be varied, simply by adding more or less bees wax. Often, increased use of your blow tube can compensate for increased temperatures.

Now is a good time to mention “Grease Cookies”. “Grease Cookies” are small wads of lubricant inserted between the powder and the bullet to make your powder fouling softer. They’re usually made in 1/8” or 1/4” thickness, inserted in the case between 2 wads, in between the powder and the bullet. A lot of shooters with big cartridges like the Sharps 45, 2 7/8ths (45-110) and the 3.25” (45-120) use these as they take up case capacity, reduce recoil (due to the lesser charge) and help soften the increased fouling that these cartridges produce. You can make them by buying a lube extruder or using a rolling pin to flatten out your material to your desired thickness. For the rolling pin method, use two flat sticks the thickness of your desired cookie width as guides for your rolling pin. I’m pretty ignorant when it comes to “cookies” I don’t use them.

Section 4

Loading

By now you’ve assembled your special equipment and components and are ready to load. The first step is to prepare your brass as I out lined earlier. Next seat your primers and you’re ready to begin:

Powder and Compression: When charging your case the actually weight of powder or quantity of powder isn’t as important as it is in smokeless reloading. Some shooters, myself included, weigh their charges to maintain consistency. Other shooters load by volume, they use a scale to set up their measure, and use thrown charges after that. Your charge weight is actually determined by the amount of compression you need for a given powder to burn efficiently. You will have to find this amount of required compression through experimentation, which I will detail later. No matter what, Do Not leave an airspace between the top of your powder column and your bullet! Your bullet must be seated on the top of your powder, usually with a wad in between.

(1) The first step is to determine the overall length of your cartridge. This will let you know how much of the bullet will be seated in your case. The difference between the stacking height of the powder column and your bullet seating depth is your compression amount. If you determine that your bullet will be seated .500” into your case, your powder must at least come to this level with your wad included.

(2) You then have to figure out want quantity of powder will achieve the minimum level required for your bullet and wad. Try a quantity, slow pour it through a Drop Tube and measure the height from your case mouth. If it is just over your bullet seating level, you have a starting point.

(3) Next, slow pour your powder through a drop tube. As I pointed out, your bullet seating depth will equal your max limit on compression. I.E. if your seating your bullet to a depth of .650 inside your case as measured from the case mouth, that is the depth your compression plug needs to compress to, including your wad. You can use the depth gage on your Vernier Calipers

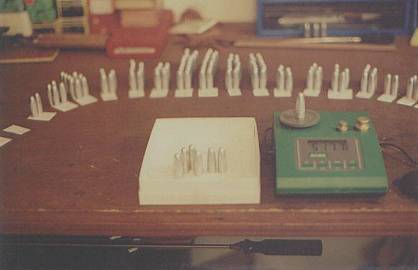

Powder Measure, scale, and Drop tube set up

to measure the depth of the compressed charge, based off the measurement of your bullet. Usually this depth doesn’t vary for a particular bullet unless you change your cartridges’ over all length (OAL). Once this is set you increase or decrease your compression amount by increasing or decreasing your powder charge. You can gently place a wad on top of your powder, not compressing it, and take a measurement. Then compress the powder with the wad, take another measurement, the difference will be the amount of compression. I.E. If your uncompressed powder measured .350 from the case mouth and your compressed charge measures .650”, then you have .300” compression. For testing purposes I usually go in 2-grain increments for rough load development. This should show either an increase or decrease in group size when you test your loads. Once my compression plug is set for a particular bullet, I measure distance from the top of the plug staff to the lock ring, using my depth gage again, and record that setting on a 3 X 5 card. This way I capture the compression settings for the different bullets used in my rifles.

(4) Once you’ve got this set and you’ve charged your cases, seated your wad and compressed the powder using your compression die. You’re now ready to seat your bullet. I shoot my bullets in ascending weight order and that’s how they’re boxed. As I stated earlier I’m a firm believer in indexing. At this point I orient the bullet in the case with my scribe lines aligned. Be careful! Ensure you do not damage your bullets’ base while inserting it. It’s a shame to ruin a perfectly good bullet by shaving lead during the last loading step due to carelessness. The case with partially hand-seated bullets are now oriented in the press shell holder. Again this is another indexing step. I like my rounds to also be oriented the same way when seating bullets.

I do not crimp my loads. In my 2.1” I leave the loaded rounds with the bell form the expander. This rifle has a loose chamber and the bell helps center the bullet in the throat. My 2.6” (Shiloh) has a tight chamber, I cannot leave the bell in the case and chamber the cartridge. For this rifle I use the seating die to remove the bell, without crimping. Generally most BPCR shooters do not crimp their cartridges. Lately there’s been some talk of crimping and enhanced accuracy due to a more consistent ignition and powder burn. The .22 Rimfire was given as an example, being heavily crimped and one of our most accurate rounds. This rational makes sense, except that Factory .22 ammo uses virgin brass with the same elasticity and therefore neck tension will not vary. Reloaded brass, even brass that’s just been annealed, will vary in elasticity and therefore neck tension.

That’s about all there is for loading a cartridge!

Use of Fillers: Some shooters advocate the use of fillers in loading their BPCR cartridges. Fillers do have practical use when loading down a big cartridge for practice. Now, here’s my take on fillers. I Don’t like them, don’t believe in them, and won’t ever use them. I believe that every variable involved with my cartridge must be as consistent as humanly possible. In that respect I’m a control freak. I look at fillers as one more variable that must be mastered if used. Also, it is an extra step that I can do without. I didn’t buy a 2.6” to turn it into a 2.1”. The old sub-sonic is good theory has pretty much been debunked. Now most guys in the winning circle want as much velocity as they can squeeze out of a cartridge. Fillers take up space that’s needed for powder.

I have several unanswered questions regarding fillers such as: How do you control the consistency of your fillers? Can you buy fillers by the lot? I understand that some shooters are using modern buffers, but to what tolerance are they? Same density? Same grain size? To believe that adding another component of questionable consistency will enhance accuracy, boggles my mind (granted, I’m easily boggled). I’m not talking about the benefit of reduced loads for practice or recoil reduction. I’m talking about being a benefit to accuracy, turning a 1.5 MOA rifle into 1 MOA or reducing your ES and SD.

I’ve never heard of anyone winning or even placing well using fillers. I read every edition of Black Powder Cartridge News I can get my hands on. I thoroughly read the equipment lists for each match that’s posted. To this day I haven’t seen mention of fillers in a winning or placing load. That in its self says something. Some of the “Big Time” shooters have much greater time and resources to dedicate to this than most of us do. If fillers worked well in the accuracy department, I’m pretty sure I’d have read about a load of 65.0 grains of powder, 35 grains of “stuff” in a 2 7/8th case winning somewhere. IMHO, winning isn’t everything, but I enjoy hitting things, it makes me happy. Hitting lots of things makes me even happier. The “Big Time” shooters hit lots of stuff all the time. Therefore, IMHO they have their act together.

For you guys that are new to this, do yourselves a favor and keep it simple at first. Powder, wad, bullet seems to work pretty well. After a few years it still takes me a couple pounds per Lot to get a load I like. I still don’t find it “easy” to get my rifles to shoot well. It takes effort each and every time. We all have varying degrees of acceptable accuracy. You’ll have to decide what yours is. Develop a load that works, understand your and your rifle’s capabilities, then play around to your heart’s content.

Section 5

Working Up a Load & Blow

Tube Use

When working up your 1st load: Keep it simple! Keep Good Records!

For a .45 caliber, get as good a bullet as possible in the 500-550 grain range about .001 or .002 over your bore diameter in a known alloy, like 20-1. The big guns often work better with big (heavy, 530-550) bullets to get a consistent ignition. I would fire-form all my brass, then give it a good neck size about .5” Select a primer like the FED 215 or WLRM to start. I would go with a known lube for starters such as Lee Shavers or SPG. You can play with various lube concoctions once you have a base idea for accuracy. Use a good wad of either .030 or .060, I’ve been having good experience with veggie, but Milk Carton with Newspaper worked well too. As I’ve pointed out, different powders like different amounts of compression. If starting with Goex, I’d go with FFG or Cartridge grade. Put enough in a case to get about .1” of compression, then .2”, then .3”, maybe even .4”. Remember, new lots of Elephant and Swiss do not need as much compression as Goex. For Swiss and Elephant I’d start at about .010” and increase gradually. Make about 5-10 rds of each compression level and test them off a good bench in ascending order.

Use a blow tube between shots, don’t count the 1st shot, possibly the second, shot in your group. A BPCR almost never shoots to the same point of impact from a clean barrel as a fouled one, I’m talking a 2-3” difference at 100 yards, it will blow your groups! I addition, I get as much as 30 FPS greater velocity from a round fired from a clean barrel! At any time during the loading process I visually identify imperfect bullets. I mark them during inspection and use them for “fouling shots”. Mark the primer with an alcohol pen to keep “fouling shots” separate. Fire the loads, hopefully you should see round groups. Stringing indicates problems; rifle, rest, hold, or load. At some point your groups will get smaller, then start to open back up. Be honest with yourself! I often have “bad” days, we all do. If I find myself testing loads during one of these periods I make a not to myself to retest that load another time. I’d hate to lose a really good load just because my shooting wasn’t up to par the day I tested it. Keep good truthful records. If it was a flyer, record it as a flyer.

At some point while increasing compression with Goex Cartridge, the boom starts to get a “Crack” sound to it. Next time out, start tweaking the smallest group producing load, a little, maybe + or - some powder, try a different primer etc. Very important when working up loads to only change one variable at a time! Once you’re down to about 2 MOA, you can fine tune by changing components, seating depth, bullet hardness, Etc. If you have a chronograph, keep good records of your MVs, ES and SD as these can tell you a lot about consistency, but not necessarily accuracy. Initial loads, I look for about 2-2.5 MOA at 200 yards, I’m happy when I get better, but that’s where the refinement comes in. An off the rack, good quality BPCR with good sights should be capable of about 2-2.5 MOA with your starting load! Pay attention to detail!

a. I cannot stress enough the importance of proper blow tube use! Some shooters seem determined to either develop loads that don’t require one or take pride in not using one. I believe that under most conditions a blow tube is essential. As I’ve written earlier one of the biggest problems with BPCR shooting is the fouling residue left by black powder. Using a blow tube in conjunction with a good bullet lube helps to overcome this and enable accurate shooting.

b. Blow tube use is relatively simple. When shooting your rifle give 4-9 breaths in between each shot, right before chambering the next round and firing. You’ll get the best results if you always blow just before firing. It makes no sense to moisten your fouling and then let it dry again before you shoot. You’ll notice that 4-9 breaths is quite a bit of variation, that’s because the proper quantity of breaths depends on conditions. In hot weather you’ll need to blow more, with the bigger cases you’ll need to blow more, less humidity you’ll need to blow more, dirty powder etc. You get the picture. I’ve shot in temperatures that required constant blowing from shot to shot. You can make a simple test during a match or at the range. Right before cleaning your rifle use your blow tube with the same amount of breaths you’ve been shooting with. Then, instead of chambering a round, run a dry patch through your barrel. This will give you an idea of what your next bullet would have traveled through. If the patch pushes through smooth and easy, all is well. If it drags in the last couple inches, either:

(1) Your lube isn’t up to par.

(2) Your bullet isn’t carrying enough lube, poor design.

(3) You’re not using your blow tube enough for your present conditions.

(4) Your load isn’t clean burning enough.

While shooting, record conditions especially temperature and wind. Watch changing light conditions, and record the results. Keep a good range notebook. I maintain records from every range I’ve ever shot on. Over time you’ll build up a fairly large amount of data about your rifle and load. It will aid you in getting that elusive “first shot hit”.

Section 5

Conclusion

That’s about it in a nutshell. As I wrote in the introduction, these are the methods that I use, they work for me. There are about as many ways of doing this as there are different people doing it. Find a method that works for you. If your results are rough at first take heart, some shooters have spent years at this and still don’t have it right. Find some local matches and ask questions. Generally the men and women that shoot these grand old guns are the friendliest in the shooting sports. They WILL help you. I cannot stress enough the need for consistency in all that you do. Hopefully, you’ll find this useful and share it with other new BPCR shooters.

Your Mileage May Vary, Chuck

PS: I’ll be updating this piece periodically, check back with me for the latest.

Standard disclaimer applies: These techniques and procedures have proved safe in my guns. I take no responsibility for you injuring yourself doing something stupid. As with all cartridge loading, proceed with caution. The author is not responsible for the condition of your rifle or equipment.

Example of my BPCR

Load Record

|

Bullet |

Powder |

Lube |

Case |

Primer |

Case Length |

OAL |

Seating Depth |

WAD |

COMP |

|

Group(s) |

MV |

SD |

ES |

Remarks |

|

|

|

|

|

Example of my range score sheet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOCATION |

|

|

|

|

|

DATE |

|

|

|

|

GUN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Distance |

EL |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

EL |

W |

|

800 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wind |

|

|

|

|

|

Temp |

|

|

Light |

|

LOAD |

|

|

|

|

None |

|

|

|

|

|

Hot |

|

Sunny |

|

|

|

|

|

|

Steady |

|

|

|

|

|

Warm |

|

Partly Cloud |

|

|

|

|

|

|

Gusty |

|

|

|

|

|

Cool |

|

Overcast |

|

|

|

|

|

|

|

|

|

|

|

|

Cold |

|

Rain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section 7

Favorite Loads

In this section you’ll find my, and other shooters favorite loads. These can only be viewed as starting points as each of these rifles are unique. What works in my rifle(s) may prove dismal in your rifle. A big thanks goes to the guys on Shooters Talk BPCR Board for their contributions to this section. They can be found at: http://talk.shooters.com/index.cfm Sports/Competition BPCR. Stop in and check this site out. Great bunch of folks, always willing to help. Here again the standard disclaimer applies! Use caution when loading! I assume no responsibility for these loads!

38-50 Remington-Hepburn caliber. Jim Ruble

Bullet: NEI #187C borerider bullet cast at approx. 25:1 seated on compressed charge and wad for an OAL of 3.385

Wad: ldpe wad cut from Prestone antifreeze jug that is .376 in dia.

Lube: My own homemade lube, but Emmert's is good enough..

Case: cases from blown out 30-40 Krag...primer flash holes drilled to .096 no sizing on case

Primer: Remington 2 1/2 primer

Powder:

62 grains by weight of Swiss 1 1/2..drop tubed thru double dia. drop tube made

of 3/8 brass tube with a 6 inch 1/8 dia. primary tube on the funnel to regulate

flow rate.

“This load will shoot under 3 inches all

day long in my 14 twist hi-wall with heavy barrel...velocity runs about 1330

fps through my tube...ES is about 15-16 fps...I have shot this load out past

800 yd. and it was very stable to that point...this bullet also performs very

well in the wind.”

40-65

Winchester W.F.Holcombe (W.F.Holcombe)

Bullet: Lyman #410663, cast from wheel weights, weighs 403.2 grns.,

weighed and sorted to 1/2 grn., seated out long (middle of second driving

band). About .002" from lands of rifling.

Wad: .030 veggie gasket material,

cut from sheets, with revised hole punch.

Lube: Home-made Emmerts' lube.

Case: Winchester 45-70 cases, necked

down to .40 caliber in RCBS 40-65 sizer die. Indexed.

Primer: Federal 215 (Large Rifle

Magnum)

Powder: 60 grns. Goex FFG. Poured

through 30" drop tube, compressed .190.

Groups: 2-2.5" at 200 yds.

P.S.: I've tried different loads; up to 68 gr. powder; more compression; different

overall length, etc. This is the one that gives the best groups with my rifle.

40-65 Win Nick Naul (N2)

Bullet: RCBS/CSA 40-400 (413 gr. from 20:1), sized .410, SPG lube,

sorted by

weight ± .5 grain

Wad: .030" Milk Carton with newspaper wad

Lube: Lee Shaver Moly

Case: RP reformed and trimmed to 2.095", flash hole and primer

pocket uniformed, neck sized .300" and expanded .407/411, sorted by weight

Primer: WLR

Powder: 56.0 Goex Cartridge, thrown

charge (Lyman 55) into 24" drop tube,

compressed .250"

40-65, (Catmasher) CPA (Stevens 44 1/2)

with 30" Badger barrel

Bullet: Steve Brooks two diameter Creedmore .400/.409, 412 gr. 1.375 inches long, cast out of new roof flashing plus tin, 40-1, casts .409, seat to 3.22 OAL.

Wad: .030 vegi gasket.

Lube: Modified Pope (leave out the graphite powder), lubed through .410 sizer.

Case: W-W trimed to 2.10, neck sized 1/4 inch.

Primer: Primer: Federal 150 Pistol

Powder: Powder: 68 grains of KIK 2F, drop tubed through 24 inch

copper tubing, compressed 2/10's inch.

note: With scope will shoot right at 1 MOA, but with my worn out right eye

groups grow to 2 1/2 inches with tang sights. That's my story and I'm sticking

to it.

40-65 (10759)

Bullet: NEI 216

mold with gas check section bored out to plainbase design. cast to .4095, lubed

through .410 sizer.

Wad: .030 LPDE Wad made from ice

cream container lids, cut with (LARGE 3 hole) office paper punch (don't laugh,

punches .410 holes).

Lube: original Pope lube-- beef

tallow 6 oz., Bayberry wax 4 oz.,Beeswax 2 oz.,synthetic sperm oil 2 oz., 1

heaping teaspoon extra fine graphite powder.

Case: W-W fire-formed, Brass sized

1/4 inch after fireforming.

Primer: Remington 2 1/2 pistol

Powder: 54gr. KIK FFg., drop tubed

through a 24" aluminium arrow shaft, compressed .085".

RIFLE: CPA Stevens 44 1/2, 30" Badger 1-16 barrel.

Note: This is the same lube that Vbull

(former national champion) has been using for the past 5-6 years. This lube is

very good. Lyman manual says you can omit the bayberry wax.

40-65 Win, Marsh Dozier Custom Hi Wall/ Snover Barrel

Bullet: 420 Paul Jones Creedmore, OAL- 2.940- touching rifling

Wad: .060 veggie fiber

Lube: Emmerts with Anhydrous Lanolin

Case: WW

Primer: WLRM

Powder: 64grs Cartridge, .300

40-82 Crossno David Brady

Bullet: NEI 216A

20:1, 425 gr, sized .408", weighed ± .5 gr and

visually inspected, seated to base of first driving band (no GG exposed)

Wad: Walters .030

Lube: Lee Shaver moly

Case: BA RP 45-70

redrawn and reformed, primer pocket uniformed,

trimmed to 2.400", expanded .407/.410

Primer: Fed - 215M

Powder: 75.0 Goex Cartridge, 30" drop tube, compressed .350"

40-2.5" SS AKA. 40-70 Straight

Nick Naul (N2)

Bullet: Saeco/Redding 740, 410 grains cast from 20:1, sized to

.411,

seated to base of first driving band (.010" jump), visually inspected and

weighed to ± .5 grain.

Wad: .030" vegetable fiber

purchased from Buffalo Arms and

punched with a Fred Cornell press

mounted punch

Lube: Lee Shaver Moly

Case: Buffalo Arms redrawn Rem 30-40 Krag, neck sized .450",

expanded with a .408/.412 expander, uniformed flash hole and primer pocket,

sorted by weight ± 1 grain, no indexing.

Primer: Federal 215M

Powder: Goex Cartridge, 75.0 grains

thrown through a Lyman 55 into a

24" drop tube, compressed .190"

40-70-2.5" SS -Ted Kramer

Bullet: RCBS .410 X 415gr. from 1-20 alloy seated so the front driving band is just in the case and a VERY slight crimp applied. Sorted to no more than 1-1.5gr difference.

Lube: SPG

Wad: .060" veggie material cut with a wad cutter turned slowly in the drill press.

Primer: WLR

Case: re-formed Remington .30-40 Krag trimmed to 2.495" and neck sized only. Expansion plug measures .4085".

Powder: 61gr Swiss 1 1/2f dropped through a 36" drop tube and compressed an additional 1/16".

40-82 Silhouette (40-2.4, aka 40-75 Winchester or a 40-65 on steroids

for it is .300 longer in the neck than the 40-65). “Dougie”

Bullet: Paul Jones 415gr 20/1

Wad: .060 Veg

Lube: Emmerts - modified

Case: Starline 45-2.4 trimmed and

squeezed

Primer: Winchester LRM

Powder: 73 grains Goex Cartridge,

weighed, poured through a 18" drop tube, wad on top, crushed just a hair

under a 1/2".

.40-70 SS dsam_bflo Sam Shiloh Creedmoor #2 Shilouette Rifle

Bullet: Steve Brooks, a .40 cal version of the 1881 Gov't design, cast 20:1, 378 gr, sized to 0.459 (the sizer hardly touches the bullet)

Wad: : 0.030 Vegetable gasket

Lube: SPG

Case: Buffalo Arms produced .40-70 cases

Primer:

Winchester LR

Powder: Elephant FFg, 70 gr (by wt),

08/99 vintage, drop tube of 40 inches, slow poured, compressed hard enough to

allow seating the bullet just past the driving band

Hand seat bullets, a slight

crimp to hold it alltogether, indexed to cases, rounds indexed to the breech at

firing

40-70bn bottleneck dave

Bullet: Saeco 740 410 grain 1-20

Wad: .30 cardboard

Lube: beeswax,neatsfoot oil,Nutragina soap

Case: reformed 348 (Buffalo Arms)

Primer: Winchester large rifle maganum

Powder: Elephant FG 70 grains

(volume) drop tube then vibrated to level amount

40-90 Snover BN, Marsh Dozier, Shiloh Sharps 74, 32” Barrel

Bullet: 460GR. Super Snover 20-1, OAL- 3.720, which fits very loose, but is pushed into the rifling.

Wad: .060 veggie fiber

Lube: Emmerts with Anhydrous Lanolin

Case: Buffalo Arms .348 sized in 40-82 Die-Fire Formed

Primer: WLR

Powder: 87grs Swiss 1.5, .090

Compression

45-2.1” (AKA 45-70) Chuck Raithel (Coydog B.)

Bullet: Lyman 457132, cast from wheel weights, 528 grns, sized to .460, seated with 1st grease groove exposed. Bullets are weight sorted, indexed and shot in ascending weight order.

Wad: Milk Carton material with newspaper over wad, cut with Fred Cornell punch

Lube: Paul Mathew’s Lube Modified with more Bee’s Wax for hot temps.

Case:. Remington, fireformed, neck sized .5”, weighed, sorted and indexed.

Primer: Fed 215 LR Mag

Powder: 67.0 Goex Cart Grade, sifted, slow poured through a 30” drop tube and compressed .302”.

MV: 1170, SD 4, ES 12 for 10 shots. Accuracy holds at a consistent 1-1.5 MOA

.45x2.1 aka 45/70 “Banjo Andy”

Bullet: NEI 349C

Gunn Modified 535gr as cast 25:1

Wad: .060 veggie with slight

compression

Lube: Own formula, Blue Hills fat

from a doe and bees wax 5:1. No Prep H unless a leaded bore. Sometimes a blob

of Ky lube added.

Case: Usually WW not sized, indexed

with bullet

Primer: WLRM

Powder: Now here's where I catch it

- 37 grains of Pyrodex Select w/4 gr kicker of Accurate #9.

I've been called many a degrading name

and snubbed as if I got the plague for using

Pyrodex BUT - Chris Hodgdon of Hodgon Powder Company has shot in our local

Schuetzen

match many times and has contributed very generously to our match and many many

others

and I must look Mr. Hodgdon in the eye when I see him! Hodgdon Powder IMHO does

more

for the shooting sports than all the other powder companies combined! I've

probably got 10

pounds or more of regular black powder in my storage box but use it only for

experimenting

and comparing to Pyrodex loads - and, I have found no black powder, including

Swiss, that

will shoot any better in any rifle I have tried!!

45-2.1”

Marsh Dozier Ballard Silhouette Model

Bullet: 540gr Paul Jones Creedmore 20-1 OAL- 2.865

Wad: .060 VEGGIE FIBER

Lube: Emmerts with Anhydrous Lanolin

Case: WW

Primer: Remington

2.5

Powder: 61.5 grs. Swiss 1.5 .065

45-2.1” JeffS CPA Stevens 45-70, 32" Badger Barrel

Bullet: Brooks copy of Lyman round noes. A little less blunt in the nose.

WAD: .030" card wad made from the card spacers between sheets of XRay film (wife's an X-ray tech and gets it from the hospital - they throw it away).

Case: Rem brass, Brass neck sized so that bullets are thumb pressed in the case, but will not fall out when turned upside down.

Primer: Winchester standard large rifle primers

Powder: 63gr GOEX 3f, 24" Drop Tube, .2" compression

approx 3" at 200yds accuracy (best my eyes can do with

iron sights).

45-2.1” anchored 74 Sharps .45-70 (Pedersoli "Sporting"

Model)

Bullet: 535 gr Postel (Lyman mold)

cast 20/1. Sized .458".

Wad: .060" Walters Veggie.

Lube: Pan-lubed

SPG.

Case: Winchester. Fire-formed.

Trimmed to 2.090". Primer hole drilled .090", uniformed, deburred.

Primer: Fed 215M "Gold Medal

Match"

Powder: 73 gr. (wt.) Goex CTG, every

charge beam-scale weighed. Slow pour (8 sec.) thru 30" drop tube.

Compressed approx. .280" with compression die.

Bullet seated .590", barely covers last grease groove, and is barely off

the rifling. Load has produced MOA at 100 yds., and did well on rams last

month. Have been finger-seating bullets, but don't like loose bullets. Next

test loads will use the above but with slight taper-crimp with Redding Profile

Crimp and OAL set with Redding Competition Seating die.

Caliber 45-70 BP Load for Buffalo Silhoute Jerry Williams,

(Brasskisser)

Bullet: Lyman 535

gr.#458125 Postell cast 30-1 shot unsized which drops from the mold at .459.

Seated above the driving band. OAL about 3.19". weight/sorted and loaded

in decending order. Cast weight about 538 gr.

Wad: One over powder wad only, 0.060

vegi fiber wad .462.

plus one over primer (under powder) news paper wad.

Lube: Home made (50% beeswax, 40%

white solid Crisco, 10% canola oil) percentages is by volume when melted.

Case: Starline 45.70 fireformed,

(after fireforming) the neck measures about .460, no resizing, I even put these

in the press and expand the neck to about .462. I file a notch on the edge of

the cartridge base for indexing the bullet and place on top when the cartidge

enters the chamber.

Primer: Federal Large Rifel Magnum hand seated

Powder: 65.5 gr. of SWISS 1 1/2

trickled slowly( about 10 sec.) through a 36" drop tube, seat fiber wad on

top of powder and compress 0.160 with compression die.

PS. I hand seat the bullet and usually

fire this way. Yes if you turn the cartridge upsidedown it will fall out. If I

carry them lose or at a match I will crimp the top just enough to hold the

bullet in the case. You can still turn the bullet in the case. Keep mak'n

smoke!

45 2.1” Humbolt

Bullet: Brooks 540 grain 30/1 bullet, pan lubed, Bullet seated with two grooves out of case

Wad: .030 King wad

Lube: Emmert’s (made with organic bees wax from very happy California bees. Lavender works best.)

Case: Remington

Primer: Rem. lg pistol primer

Powder: 73 grains Swiss 1 1/2

through drop tube, compressed in sized case

45-2.1, Steve Poteete, Uberti Hiwall, 1-20 twist, 30" Barrel

Bullet: 500gr. Lee mould, actual weight ave.508gr.RNFP pan lubed

Wad: tablet backing, punched out with 1/2" hole punch

Lube: 50/50 beeswax and Crisco

Case: Winchester 45/70

Primer: Winchester, large rifle primer

Powder: 67.0 FF Goex, 24" drop

tube and homemade compression bullet

Chrony test: 1230 fps ave.

45-2.1”

“Bump”

Bullet: Buffalo Arms Postell Bullet

Wad: .030 veggie wad, 2 newspaper wads (1 over the primer & 1 under the bullet base)

Lube: SPG

Case: Rem brass (with flash hole cleaned up)

Primer: F210M primers

Powder: 67gr Goex Cart

45-2.4:

SS, (often incorrectly called the 45-90)

Nick Naul (N2)

Bullet:

NEI/Gunn 349C, 540 grains cast from 20:1, sized to .460",

seated to base of first driving band

(.008" jump), visually inspected and

weighed to ± .5 grain, seated with

Redding Comp Seating die.

Wad:

.030" vegetable fiber purchased from Buffalo Arms and

punched with a Fred Cornell press

mounted punch

Lube: Lee Shaver Moly

Case:

Buffalo Arms redrawn Rem 45-70, neck sized .400", expanded

with a .458/.462 expander, uniformed

flash hole and primer pocket, sorted by

weight ± 1 grain, no indexing.

Primer:

Federal 215M

Powder:

Goex Cartridge, 85.5 grains thrown through a Lyman 55 into a

24" drop tube, compressed

.170"

45-2.4” 45-90 “Marc”

Bullet: Mike

Lewis, similar to various "Creedmoor" style slugs, first driving band

0.002" over bore dia. 1:25 Sb/Pb, 544 grns, unsized, seated with scraper

groove and one grease groove showing. Bullets are sorted by histogram and shot

in +/- 0.1g weight groups. Indexed. Chicken load is identical as below but with

Lyman 457693, 424g flat nose.

Wad: .060 LDPE Wad, bought precut

from Buffalo Arms.

Lube: 50/50 Beeswax and Olive Oil.

Case: Buffalo Arms

"stretched" .45-70. Sized using std. .45-70 die backed off the

shell-holder 0.300". Flash holes opened to 0.096", deburred inside

and primer pockets uniformed. No indexing.

Primer: WIN Large Rifle.

Powder: 86.5g Elephant FFg, vibrated

to settle, 0.030" max compression.

45-2.4” (45-90) “redleg” Shiloh 45-90 LRE

Bullet: SAECO

1881 Gov't 30-1 fully seated

Lube: SPG

Case: Buffalo Arms, sized in Lyman

neck sizer about 3/8 inch, Buffalo custom expander plug 457-461

Primer: Fed 215

Powder: 70 gr KIK lot 004 just a

touch of compression with bullet 24 inch drop tube

Velocity: 1240-1250fps

45-2.6” Sharps Straight (AKA 45-100) Chuck Raithel (Coydog B.)

Bullet: NEI 349F Paul Jones Creedmore, cast from wheel weights, 542 grns, sized to .460, seated to front driving band. Bullets are sorted by weight, indexed, and shot in ascending weight order.

Wad: .030 Veggie Wad, material from Buffalo Arms, cut with Fred Cornell punch

Lube: Lee Shaver Moly Lube

Case: Buffalo Arms reformed .348 Winchester, fireformed, neck sized .5”, weighed, sorted and indexed.

Primer: WIN Large Rifle magnum

Powder: 96.0 Goex Cartridge Grade, sifted, slow poured through a 30” drop tube and compressed .320”.

MV: 1276, SD 4, ES 11 for 10 shots. Accuracy holds at a consistent 1-1.5 MOA

45-2.6” Sharps Straight (AKA 45-100) Chuck Raithel (Coydog B.)

Bullet: NEI 349F Paul Jones Creedmore, cast from wheel weights, 542 grns, sized to .460, seated to front driving band. Bullets are weight sorted, indexed and shot in ascending weight order.

Wad: .030 LDPE, material from Buffalo Arms, cut with Fred Cornell punch

Lube: Lee Shaver Moly Lube

Case: Buffalo Arms reformed .348 Winchester, fireformed, neck sized .5”, weighed, sorted and indexed.

Primer: WIN Large Rifle

Powder: 91.0 Swiss 1.5F Grade, sifted, slow poured through a 30” drop tube and compressed .140”.

MV: 1310, SD 5, ES 13 for 10 shots. Accuracy holds at a consistent 1-1.5 MOA

45 2.6 SS(45-100) Jimmy R. Baker

Bullet: Paul

Jones Creedmoor; 543 grains, 20/1, unsized, pan lubed, weighed and sorted to

1/2 grain. The front driving band engages the rifling.

Wad: .030 vegetable from Buffalo

Arms, punched with Cornell wad punch

Lube: Modified Emmert's

Case: 348 Winchester from Buffalo

Arms, neck sized, expanded with .458/.462 expander from Buffalo Arms

Primer: Winchester Large

Pistol(white box)

Powder: 101.5 grains Elephant 2f;

poured through 36" drop tube, compressed .110

45-2.6" David Brady

Bullet: NEI/Gunn LR 349J NP (20:1, 565 gr.), sized

.459, weighed ± .5 gr and visually

inspected, two GG exposed

Wad: Walters . 030

Lube: Lee Shaver Moly

Case: Buffalo

Arms .348 Win redrawn and reformed, primer pocket uniformed,

trimmed to 2.600", expanded .458/.462

Primer: Fed - 215M

Powder: 97.0 Goex Cartridge,

.100" compression (long throat Gullo

reamer), 30" drop tube

45-2.6 Marsh Dozier Sharps 74, 32"

Badger Barrel

Bullet: Paul Jones Creedmore 540gr, 20-1, OAL- 3.369 ( bullet seated off rifing for ease of chambering in dirty barrel.)

Wad: .030 Veggie Fiber

Lube: Emmerts with Anhydrous Lanolin

Case: BUFF Arms .348

Primer: WLR

Powder: 85.5 grs Swiss 1.5, .085 Compression

.45

2 7/8 AKA .45-110 Sean Thornton

Bullet: Lyman

#457132 Postell, cast from wheel weights, weighs 528 grns., weighed and sorted

to 1/2 grn., seated at first driving band

Wad: .060 Walters Wad

Lube: SPG

Case: Norma .45 Cylindrical

Primer: WLR

Powder: 100 grns. Swiss 1 1/2 Fg

Poured through 24" drop tube, compressed .125, right at 1400 fps.

Groups: 3.5 to 4 inches at 200 yds. 11 inches at 500 yards

“This load works great but it does let

you know when it goes off.”

45

X 2 7/8" Sharps Straight (AKA 45-110) Scott Ross “Longrider”

Bullet: Tom

Ballard "Modified" Postell 530gr. (20:1) Modified being instead of a

driving band right behind the ogive, it starts with a grease groove. Nose pour.

Bullets are cast and examined for flaws, not weighed. Pan lubed. Not sized.

Indexed and hand seated to touch the rifling upon chambering. No punch marks in

my mould for indexing, I index off the parting line and direction of the swipe

of the sprue plate.

Wad: .060 Veggie Wad, material from

NAPA, cut with Cornell punch

Lube: Longrider's Sooper Loob #2

(AKA Home brew)

Case: NORMA, fire-formed, indexed to

headstamp. NORMA headstamps during the forming process and IS (I'm told) a

consistent position, not just random placement. I don't index to a thick or

thin side of my brass, I just index to keep the fireformed case at a constant

orientation with the chamber. Brass not sized after fireforming.

Primer: Fed. 215M "Gold Medal

Match"

Powder: 105gr. Goex FFg., slow

poured through a 36" drop tube and compressed .300".

RIFLE: Shiloh Long Range Express, 34" #1 Heavy barrel.

Note: If the shooter (ME) does his part,

this rifle and load will perform admirably with 1.25 to 1.5 MOA being quite

common. But then again, if the shooter (ME again) has his head up his butt like

he did at the Q this year, this rifle and load will still perform admirably but

the shooter should get the stick! :-)

45 2 7/8 (45-110) XXGrampa

Bullet: Ideal 457125 500gr linotype

(mold is 60+yrs old)passed thru a saco sizer with a die big enough to apply

lube and not touch the bullet.

Wad: None, bp special mix#47 buffer from top of powder column to case mouth. bullet pushed in to compress filler and for an oal to just touch the rifling.

Lube: Mix of marine wheel bearing grease and beeswax in barrels over 30 inchs, lee shavers in 30 and under.

Case: 45-110 Norma, Un-sized, however cases my be finger pinched just enough to keep the bullet from falling out

Primer: Fed Large Rifle Match

Powder: Goex 2f. (made in the good

old USofA) 40 to 100grs. depending on target. and to control barrel whip.

Compression: none. powder compacted by vibration and a two inch weight.

WARNING: As I wrote earlier, I do not advocate the use of “Fillers”. Improper use can damage to your rifle.

45-110 (2-7/8) Everett

Bullet: 540 gr. NEI P.J. Creedmore 20-1 mix 2 and 1/2 rings exposed with no neck tension except for a very light taper crimp to hold bullet in place.

Wad: .060 veggie wad over the powder with a grease (Homebrew) cookie and another .030 wad over the whole thing.

Lube:

Case: Buff Arms stretched brass (fireformed)

Primer: Fed Match Grade 215 primers

Powder: 100 gr. Swiss 1.5 poured

down a two foot drop tube. Each load is weighed.

All loads are indexed. These loads are not as punishing as you all might think.

My Sharps has a standard heavy 34" barrel. These rounds are better than I

am a shooter. I Like those large wind cutting heavy bullets with a little

something behind them besides the "Nut Behind the Butt" I have good

results with this load in windy, in all directions at once, conditions that we

see on the prairies of Eastern Montana as most of you Quigley shooters can attest.

45-110, Roy* Shiloh Sharps LRE

with Badger 34" heavy octagon

Bullet: Brooks version of Jones Creedmore, 555 gr out of 20-1, casts 460, sized .459, seat to 3.65 OAL.

Wad: .060 veg fiber, Cornell punched.

Lube: Black Magic, pan lubed.

Case: Buffalo Arms stretched .348, fire formed, sized about 1/2". Note: I have to keep after trim length with these cases, but not with the stretched R-P 45-70's in my 45-90. Go figure.

Primer: WLMR

Powder: 4.0 gr 4759, then 88 grs 2F

Elephant 25/99, drop tubed 30", both amounts by weight.

I scoop the 4759 with a Lee #020 scoop,

drop the main charge from a Lyman 55 with a brass hopper and a baffle. The drop

tube is installed direct in the measure with a restrictor made from a .250

Savage case with the head cut off in the top, to slow-pour. I use the knocker

to avoid bridging.

I duplex to reduce fouling, not for power. This load is approximately the same

as 100 gr of black, and chrono's 1280 fs, SD is 6.

.45 x 3.25" (AKA45/120) Clive Taylor “ The Brit”

Bullet: NEI 349J cast from new flashing lead (99.6% pure). Casts at 585 grn nominal and .461 dia. and are not sized. Bullets are weighed and batched in groups 583.6/584.5, 584.6/585.5, 585.6/586.5 anything above or below discarded (very few). I generally cast 500 - 1000 at a time which makes this technique viable. Comps. shot from one batch. Not indexed. Finger seated. Not crimped.

Lube: Home brew. Pan lubed. All grooves filled.

Wad: Wax card

from milk carton. Punched with die cutter made by Charlie Higginbottom

Grease Cookie: 11mm thick of home

brew. Cookie cut from pan.

Beeswax Wad: Cookie cut from Hive Starter sheets.

Case: HDS trimmed to 3.245. Not resized at all.

Not sorted or indexed. Scrubbed internally after shoot and vibrated in crushed

corn and brasso for 2 hours before reloading.

Powder: Kicker load of 45 grains of

Swiss #4 (1.5fg to you) poured into case. 70 grains of Wano fg (socked) poured

into case. Both charges are weighed using Dillon D-Terminator. Compressed

.5" using Buffalo Arms compression die.

Primer: Remingtom 9 1/2 Large Rifle

seated with Lee Auto Prime

50-70 rdnck

Bullet: Lyman 515141 sized to .510 after lubing.

Wad: Usually

none. If used, it is cut from wax paper. There is not enough room in the case

for any thicker wad, or more compression.

Lube: Black Magic, applied by

dipping.

Case: Bell, full length sized and neck expanded.

Primer: WLR

Powder: GOEX 2f, 70 grains, dropped

through a 30 inch tube. This fills the case to the top. Compression: .450 from

the top of the case mouth.

Bullet is seated with all the grease

grooves covered, and sits on top of the wad/powder. Velocity is 1225 and the sd

runs from 5 to 7. In my original Roller it stays under 2 inches at 100 yards.

It is magic on deer, and last year I dumped a coyote at a laser measured 201 yards

with it. This is a really great hunting round and is loads of fun to shoot.

Shoot straight, rdnck.

50-90

bottleneck dave

Bullet: Saeco 650 grain 1-20

Wad: .60 cardboard

Lube: Beeswax, neatsfoot oil, nutragina soap

Case: Bell

Primer: Fed. 215

Powder: Elephant Fg 110 grains

(volume) drop tubed then vibrated to level amount

.577-.450 Martini – Henry Swiss Bob

Bullet: Lyman Paper Patch mold 480gr. .446 dia. patched up to .460". 100% cotton paper .004" thick. Patch tail cut off leaving just a 1/16" rim of paper folded over the base of the bullet.

Wad: .030" Orange Juice Box wax wad over the powder, .030" Orange Juice Box wax wad used on top of lube cookie/under the bullet.

Lube: Paper patch lightly lubed with Imperial Sizing Die wax. 3/16" Emmerts lube, grease cookie used in neck of case.

Case: .577-.450 Martini Henry made by NDFS

Primer: Federal

Mag. Match 215M

Powder: 93gr 2fg KIK black powder,

dropped through 36" drop tube then compacted about .200"

Loading for the 45-70 Trapdoor, By “Minnesota Al”

Here’s a 45-70 Trapdoor Load for beginners. This load works

very well in several Trapdoor rifles I’ve tried. With once fired cases the

equipment needs are very minimal – this is cheap to fabricate and shoot.

Lee 405 Gov’t hollowbase bullet. This mold casts well and will last much longer

than their 500 gr Gov’t design – my 1881 500 Gov’t fails to align after maybe

1000 bullets cast and the thing never did shoot very well.

25:1 alloy, sized to .459 (sizing probably not needed).

Lube 50/50 beeswax and olive oil – pan lube works.

No wad (hollow base bullet). Wipe lube off the base of the bullet before

seating.

FFG Powder – Goex 63 gr or 70 gr Elephant. Both compressed about .15” to allow

the bullet to seat .65” into the case. Drop tubed. You’ll need a compression

die to get this compression, don’t use the bullet. If I wanted to go without

compression I would shoot Swiss 1.5 and drop tube just enough to fill the case

to the base of the bullet. About 62-63 gr of drop tubed Swiss should yield the

proper height with no compression.

Federal 215 primers

W-W cases, not resized.

Finger seated bullets, although a Trapdoor seems to ding the cases just enough

that this can be difficult. Some bullets will need a seating die, especially if

not sized.

If you want to be able to carry your bullets in a cartridge belt you should

obtain the Lee Crimp die for the 45-70 (available from Pat Wolf). I can put a

slight crimp on the bullet that will let the bullet rotate in the case, but

still holds it in place.

If loading into brand new cases you will need to expand the case mouth as far

as a standard expander die will allow. And even then the bullet will get

greatly squeezed when seating it. Don’t expect fabulous accuracy from these

loads. Once fired cases will be easier to load and give better accuracy.

AL